Unlocking the Advantages of Superior Air Control Valves for Enhanced Performance

In today's competitive industrial landscape, the efficiency and performance of systems largely depend on components such as Air Control Valves. According to a recent report by MarketsandMarkets, the global air control valve market is projected to reach USD 9.1 billion by 2025, growing at a CAGR of 4.1%. This emphasizes the pivotal role these valves play in optimizing fluid dynamics and enhancing operational efficiencies across various sectors, including manufacturing, automotive, and HVAC. Superior air control valves not only ensure precise airflow regulation but also contribute to energy savings, reduced emissions, and improved system reliability. As industries increasingly prioritize performance and sustainability, investing in high-quality air control valves can unlock significant advantages, ultimately leading to enhanced productivity and cost-effectiveness.

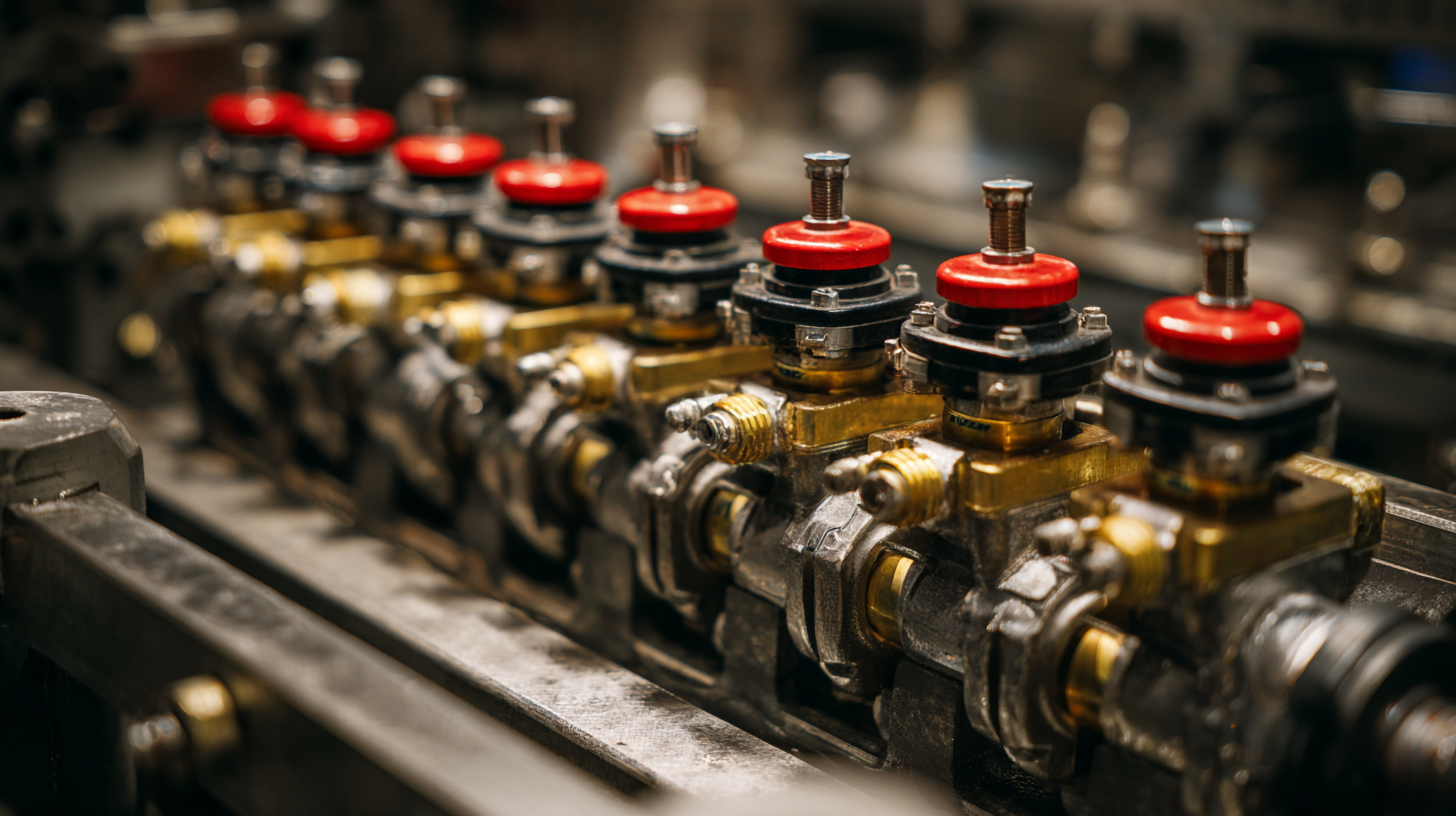

Types of Air Control Valves and Their Specific Features for Optimal Application

Air control valves are integral components in various pneumatic systems, ensuring optimal airflow and pressure regulation. Understanding the different types of air control valves can significantly enhance system performance. For instance, the needle valve provides precise flow control, making it ideal for applications requiring fine adjustments. On the other hand, the globe valve is known for its ability to maintain the flow direction and reduce pressure drops, suitable for larger systems.

When selecting an air control valve for your application, consider specific features such as the valve's size, material, and response time. For pneumatic systems handling corrosive materials, a valve made from stainless steel offers durability and resistance. Tips include regularly inspecting valves for wear and maintaining clean air filters to prolong valve life and ensure efficient operation.

Another essential type is the quick exhaust valve, which allows for rapid venting of air, speeding up actuator response times. This feature is crucial in applications where precise timing is paramount. Always ensure the compatibility of the valve with your system's specifications to avoid operational issues.

The Role of Pressure Drops in Selecting the Right Air Control Valve

Selecting the right air control valve is crucial for optimizing performance in a variety of applications, particularly when considering the impact of pressure drops. Pressure drops occur when air flows through a valve, creating resistance that can affect system efficiency. Understanding how these pressure variations influence the selection process is essential for engineers and designers. A superior air control valve should minimize unnecessary pressure drops, which not only enhances the performance of the system but also improves energy efficiency.

When evaluating air control valves, it’s important to analyze the specific pressure drop requirements of your system. A valve that is too restrictive may cause significant pressure loss, leading to increased energy costs and reduced system effectiveness. Conversely, an appropriately selected valve can balance airflow and pressure, ensuring optimal operation.

Factors such as valve size, design, and the types of materials used can all contribute to how well a valve performs under varying pressure conditions. Choosing the right valve not only augments operational efficiency but also prolongs the lifespan of the overall system by reducing undue stress and wear.

Materials and Construction: Evaluating Durability in Air Control Valves

When it comes to air control valves, the materials and construction play a pivotal role in determining their durability and performance. Selecting the right materials not only enhances the valve’s lifespan but also mitigates potential issues caused by environmental conditions. For instance, stainless steel and brass are commonly used due to their resistance to corrosion and ability to withstand high pressures. These materials ensure that the valves maintain functional integrity over time, reducing the need for frequent replacements and maintenance.

Moreover, the construction quality significantly influences the valve’s overall effectiveness. Precision engineering techniques must be employed to create tight seals that prevent leaks and ensure optimal airflow. This precision also contributes to the valve’s ability to operate efficiently under varying temperature and pressure conditions. Advanced designs, such as those incorporating reinforced fittings or innovative sealing methods, can significantly extend the operational life of air control valves, making them a worthwhile investment for industries relying on efficient air management systems.

Performance Metrics: How Superior Valves Impact System Efficiency and Energy Savings

Superior air control valves are pivotal in optimizing system efficiency and enhancing energy savings across various industries. According to a study by the U.S. Department of Energy, implementing high-quality valves can improve air handling system performance by as much as 25%. This significant improvement is not just about increased airflow; it also ensures that the systems operate at optimal pressures, reducing wear and tear over time. Enhanced designs with better sealing capabilities can also minimize leakage, which is crucial as research indicates that up to 30% of energy in HVAC systems can be lost due to inefficient airflow management.

Tips for maximizing performance: First, ensure regular maintenance of air control valves to detect wear and prevent leaks. Scheduled inspections can help in identifying potential issues before they escalate, saving time and costs. Additionally, consider upgrading to electronic or advanced pneumatic control valves for precision operation. These modern valves can dynamically adjust to real-time system demands, which not only increases operational efficiency but also contributes significantly to energy savings.

Furthermore, it’s vital to evaluate your existing air control system periodically. Data from the American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE) suggests that enhancements in valve technology can lead to reductions in operational costs by up to 20%. By investing in superior air control valves, businesses can ensure they meet both performance standards and sustainability goals effectively.

Industry Trends: Innovations Shaping the Future of Air Control Valves

The automotive HVAC system market is witnessing substantial growth, projected to reach an estimated 34.81 billion by 2032. This increase can be attributed to a rise in consumer demand for energy-efficient and environmentally-friendly solutions, leading to innovative advancements in air control valves. As part of the HVAC system, superior air control valves play a crucial role in optimizing climate management within vehicles, enhancing both passenger comfort and system performance.

Industry trends indicate a focus on developing smarter air control valves that leverage advanced technology to monitor and regulate air flow more effectively. Innovations such as electronic controls and integrated sensors are reshaping the landscape, allowing for precise temperature regulation and improved energy efficiency. Moreover, the emphasis on sustainability is driving manufacturers to pursue eco-friendly materials and practices, ensuring that the next generation of air control valves meets consumer expectations while minimizing environmental impact. These trends not only reflect the evolving automotive industry but also highlight the critical role of air control valves in enhancing overall system performance.